Commencement of Sales of Resin Molding Simulation Software PD Advisor® 3.0

First in industry to come with function that proposes optimal design against deformation during molding

Mar. 31, 2022

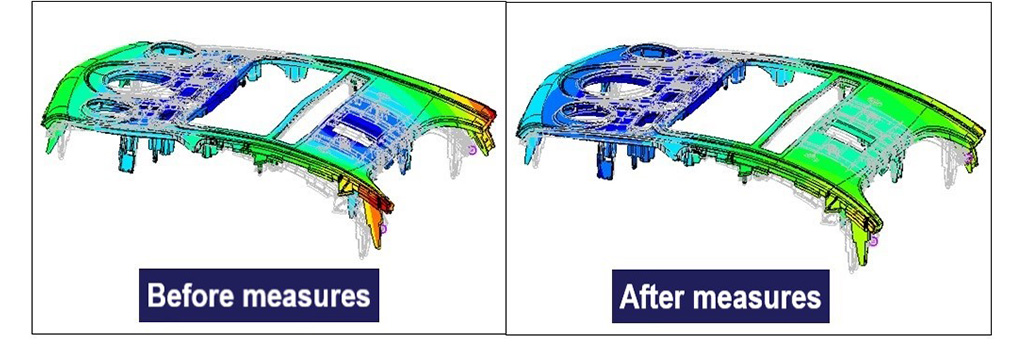

Toray Engineering D Solutions Co., Ltd. (Head office: Chuo-ku, Tokyo, President & CEO: Ryo Nakano, hereinafter ‟TDS”) announced that it has developed PD Advisor® 3.0 that comes with a function that proposes designs which suppress deformations. This is a new version of the PD Advisor® software that simulates deformations—such as warping that occurs when molding resin parts—during the design stage. Sales of the new software will commence in April. Although there are already systems which can predict deformations that occur during molding, this is the first system in the industry with a function that proposes measures against deformations based on predictions.

Using its feature of being able to efficiently carry out design resin parts that require shape and dimensional accuracy, the plan is to provide proposals to manufacturers of resin parts for automobiles and electronic equipment.

The sales target is 30 sets of licenses in FY 2022 and 50 sets of licenses in FY 2025.

In 2020, PD Advisor® started to be sold as a system that predicts deformations—such as warping caused by the thickness and shape of resin parts—in the design stage. TDS also offers 3D TIMON®, a software that simulates changes in shape arising from molding conditions during mass production. By combining them to offer proposals, TDS is contributing toward making the manufacturing of resin parts more efficient from both aspects of design and mass production.

In resin molding, molding conditions—such as the part’s thickness and shape, and the temperature changes after being poured into the mold based on the temperature and pressure during molding—cause minute variations in the resin’s cooling conditions, which affect the molded product’s dimensions and shape. Therefore, it is difficult to predict and control the molded product’s shape. Furthermore, parts being used in automobiles, electrical devices, and such have complex shapes, yet require a high level of constancy in dimension and shape. The molding of these parts requires exact predictions after considering a variety of conditions.

In the past, PD Advisor® has been offered as a software that predicts deformations during molding caused by shape. By combining TDS’s analysis technology that outputs deformation factors with high sensitivity and design technology that uses such data to produce thickness that does not deform easily, the company succeeded in adding a function that proposes designs which avoid deformations. This allows the design process—which required adjustment of actual molding conditions and a high level of knowledge and experience—to be carried out efficiently and can contribute toward shortening the development period.

This software can also be used as a 1D CAE* tool compatible with model-based design (MBD), a method for carrying out development within short periods of time while conducting simulations using models derived from analytical data and theoretical formulas. This method is gaining wider use in various industrial fields, including the automobile industry.

Toray Engineering D Solutions will contribute to society through providing proposals that solve all kinds of issues faced by manufacturing sites by making full use of its technology, engineering technology, and know-how.

The details of PD Advisor® 3.0 are as follows.

| Product name | PD Advisor® 3.0 |

|---|---|

| Product features |

|

| Usage | Manufacturers of resin parts for automobiles and electronic equipment |

| Sales goals | 30 sets of licenses in FY 2022 50 sets of licenses in FY 2025 |

<Simulation images>

- 1D CAE (Computer-Aided Engineering)

This is analysis that is conducted to accurately grasp the essence of the matter and express it simply in a format with good prospects in order to have an overview of the entire product and carry out appropriate design from the upstream stage. PD Advisor® accurately grasps the warping phenomenon of resin parts, expressing it simply using several factors for use in analysis.