- HOME

- Products and Services

- Factory Automation

- Core Technologies

- Riveting

Riveting

This equipment rivets large metal parts with high strength and precision. Our unique handling and positioning technologies measure and compensate for bending and distortion while riveting parts.

Proprietary Technologies

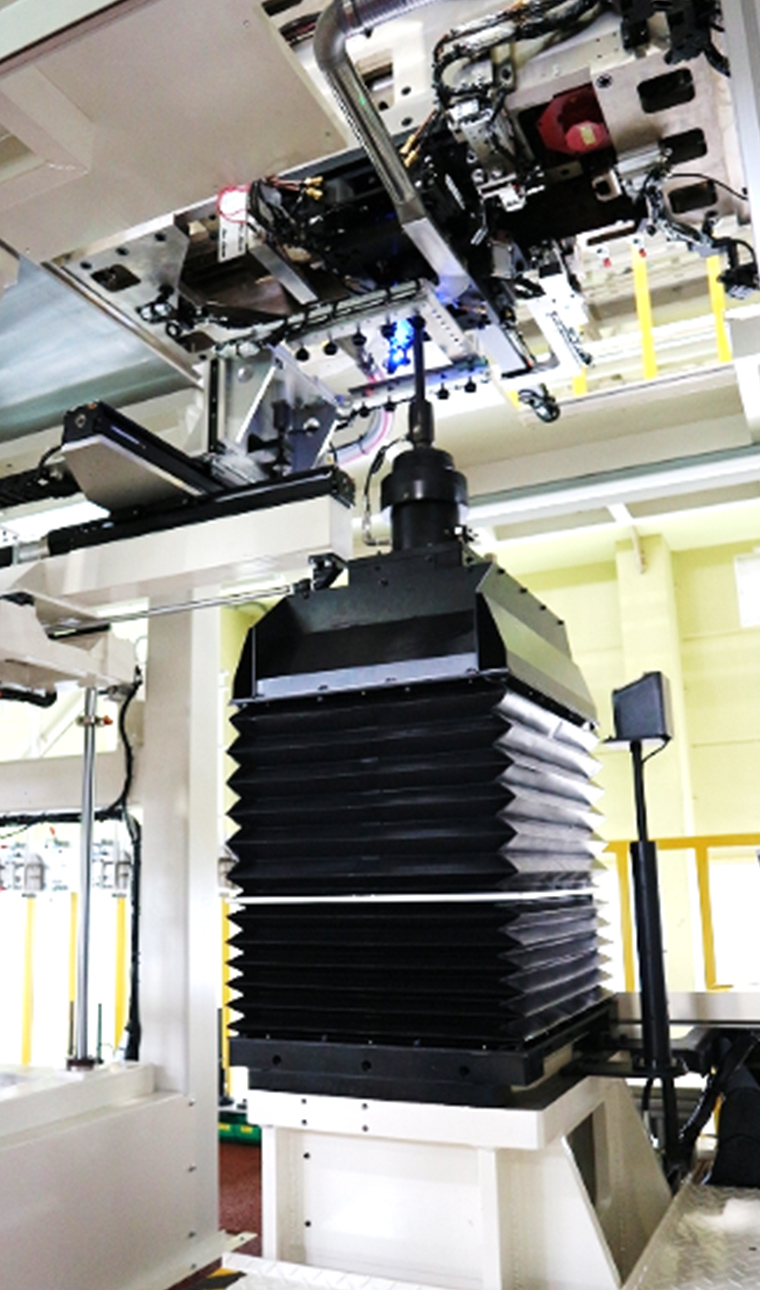

Vertical Riveter

Features

- Precise, high-speed drilling and riveting

Supported Materials

- Aluminum, thin steel sheets, carbon composite materials, etc.

Applications

- High-speed, precise processing tests (4 seconds/hole from drilling to swaging)

- Able to swage fasteners with large shaft diameters (approx. 9mm in diameter)

- Detects and punches out the center of temporary fixing studs

- Press fitting of fasteners (up to 9mm in diameter)

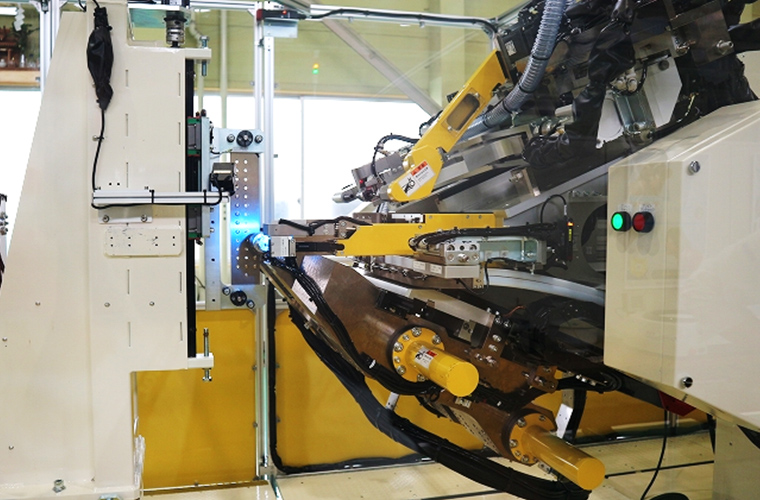

Horizontal Riveter

Features

- Drilling and riveting in narrow, hard-to-reach areas

Supported Materials

- Aluminum, thin steel sheets, carbon composite materials, etc.

Applications

- Riveting with reinforcing members such as reinforcing rib

- Processing near walls with small processing head

- Press fitting of fasteners (up to 6mm in diameter)

- The above test equipment facilities are located in the Numazu Plant in Numazu, Shizuoka Prefecture.

Introduction Example

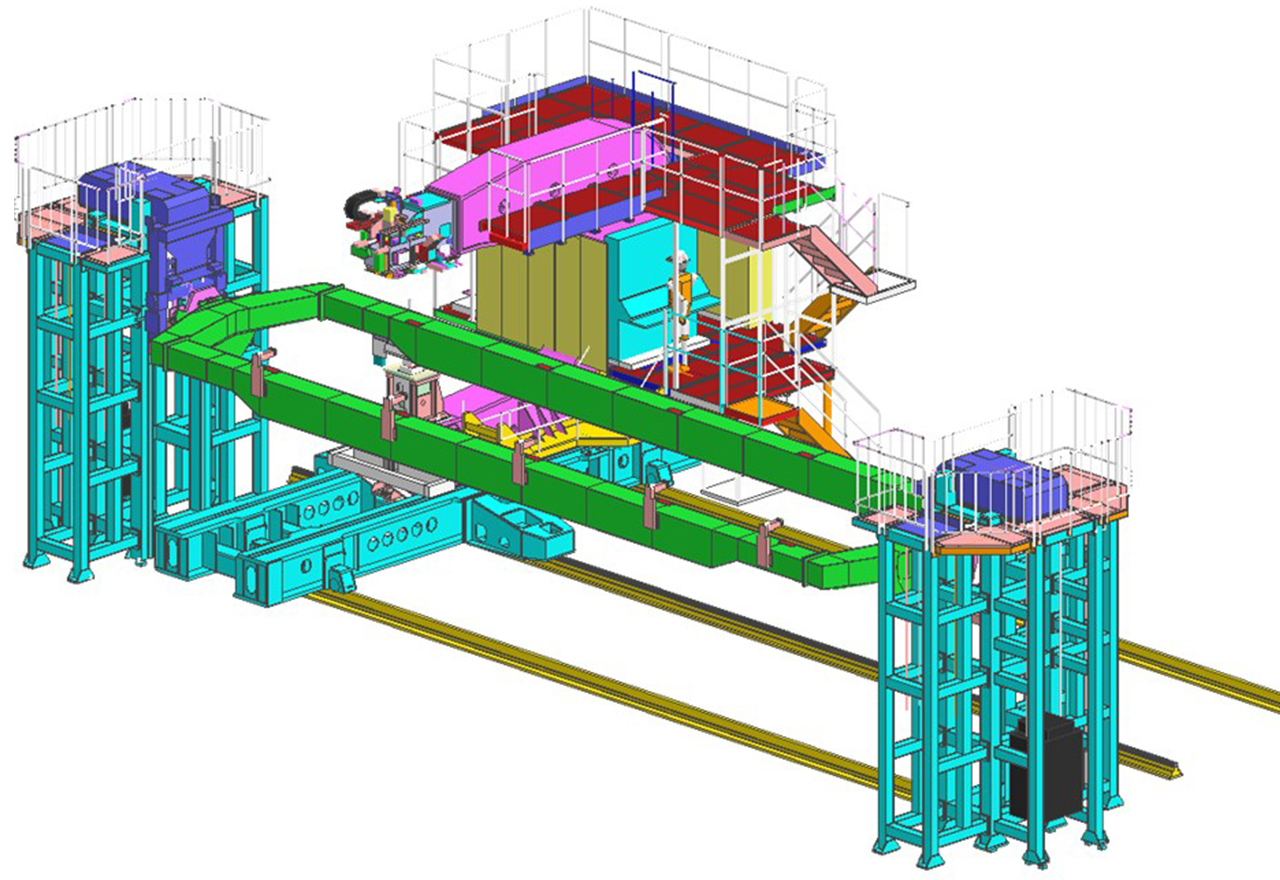

Aircraft Riveters

High-precision riveting of aluminum skin outer panels to structural members of aircrafts