- HOME

- Products and Services

- Film-Production Equipment

- Film Production Line

- Film Production Line

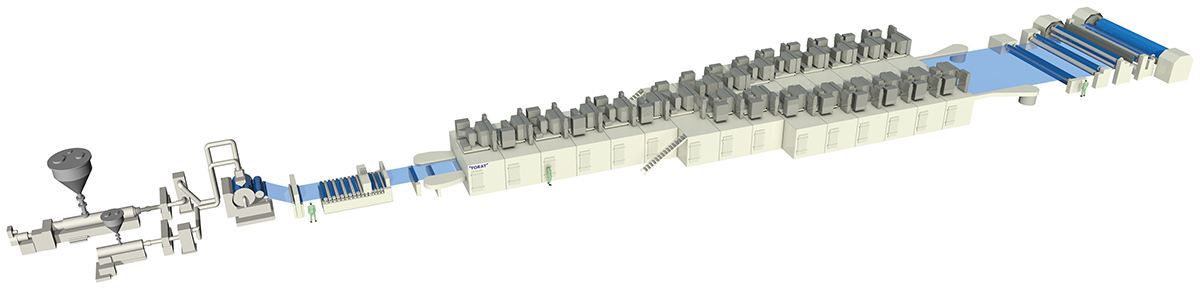

Film Production Line

Based on our extensive track record and know-how, we offer optimal film production lines for a wide range of purposes from high-functionality films to general-purpose films.

Features

- Able to produce various types of films with different thicknesses

- Integrated engineering solution from extrusion to winding

- Can provide single pieces of equipment

- Responds to customer's environmental requirements such as clean room type, explosion-proof specifications and inert gas purging.

- We can customize film production machinery to meet your requirements.

Film Production Line

Film Production Line

Filtering Machine

Specifications

- Leaf disk type filter

- Disk type filter

- Tube type filter

- Screen changer

We propose filters such as the above to suit your applications.

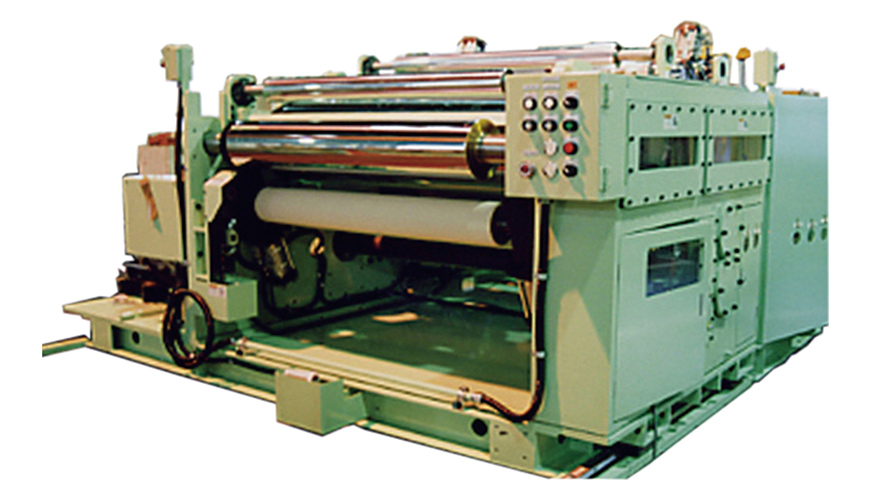

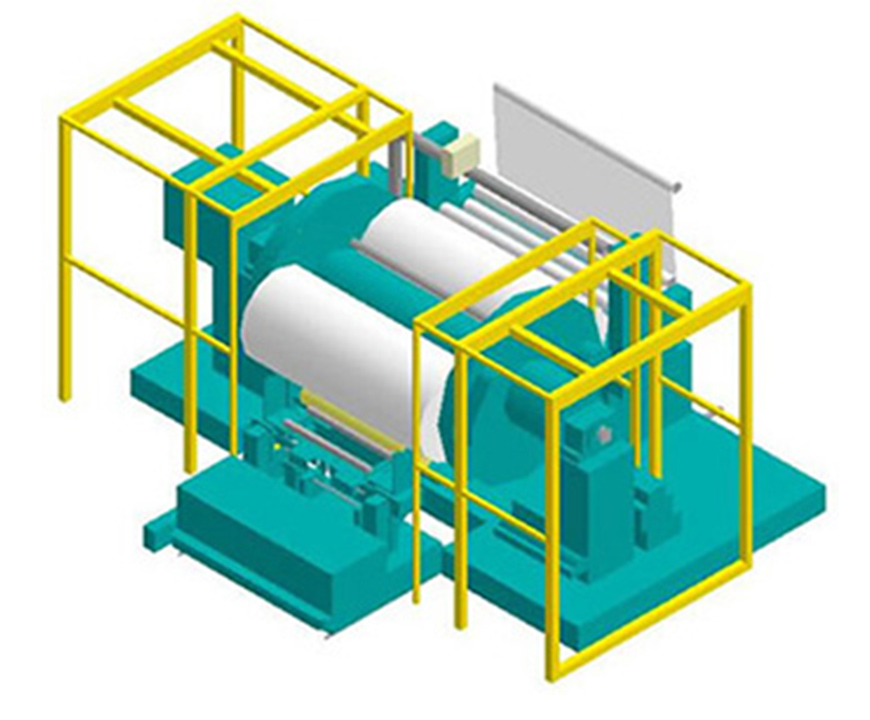

Casting Machine

Description

Achieves stable casting while minimizing casting drum speed error.We have extensive know-how for achieving stable temperature management and facilitating attachment of film to drums!

Specifications

| Types | Drum types (1-drum, 3-drum) |

|---|---|

| Film width | Max.2,300mm |

| Machine speed | Max.100m/min |

| Drum width | 3,000mm |

Incidental equipment

- Drum elevator

- System for drum to move for MD

- Roll to pick up film

- Air chamber

- Device for pinning (wire pinning, air knife)

- Pinch Roll

- Film threading unit

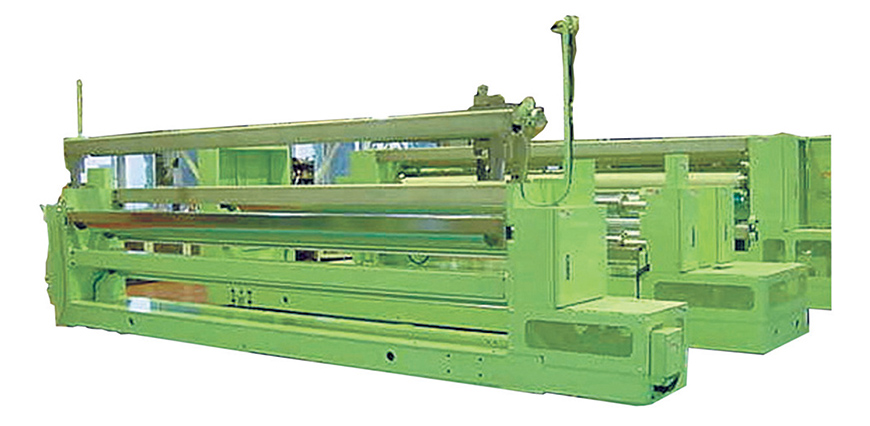

Longitudinal Stretching Machine

Description

We propose roll layout, roll surface treatment, temperature management systems and machine features, from preheating to stretching to cooling, to suit your film material.

- Roll layout

- Roll surface treatment

- Temperature management systems

- Machine features

Also facilitates maintenance.

Specifications

| Film width | Max.2,800mm |

|---|---|

| Machine speed at exit | Max.450m/min |

| Stretching ratio | Max. 5 (Enables multistep drawing) Individual running gear |

| Method to heat roll | IR (induction heating), Warm water, Steam, Oil |

Incidental equipment

- Film threading unit

- Device to clean roll

Transverse Stretching Machine

Description

Customized for the product

- Able to automatically adjust stretch ratio

- Nozzle design allowing uniform temperature distribution

- Clean and explosion-proof

- Heating oven for neutral gas environment

- Optimal clip design

Specifications

| ilm width | 3,000~8,700mm |

|---|---|

| Stretching ratio | Max. 10 times |

| Oven length | Max. 10 times 5,700mm |

| Oven width | 5,000~14,000mm |

| Oven temp. | MAX 400℃ |

| Rail length | Max. 67,300 mm (turn foil to turn foil) |

| Nozzle length | MAX 9,900mm |

| Oven heating method | Oil; electric; steam; gas |

Take-up Machine

Description

Various options are available

Specifications

| Film width | Max.8,700mm |

|---|---|

| Machine speed | Max.450m/min |

Incidental equipment

- Spreading device (film guide, grooved roll)

- Embossed roll

- Edge trimming unit

- Edge film handling unit

- Static-eliminator

- Surface treatment unit

- Film threading unit

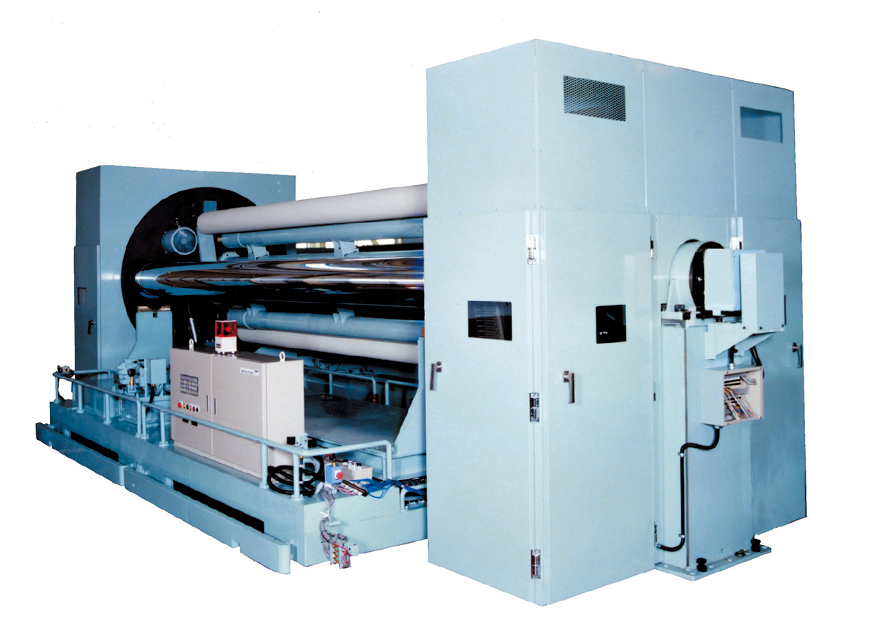

Mill Roll Winding Machine

Description

Achieves high-accuracy and high-quality winding using automatic continuous running

Specifications

| Film width | Max.4,900mm |

|---|---|

| Machine speed | Max.250m/min |

| Contact winding, gap (near) winding | |

Incidental equipment

- Transverse cutting for thick films

- Transverse cutting for thin films

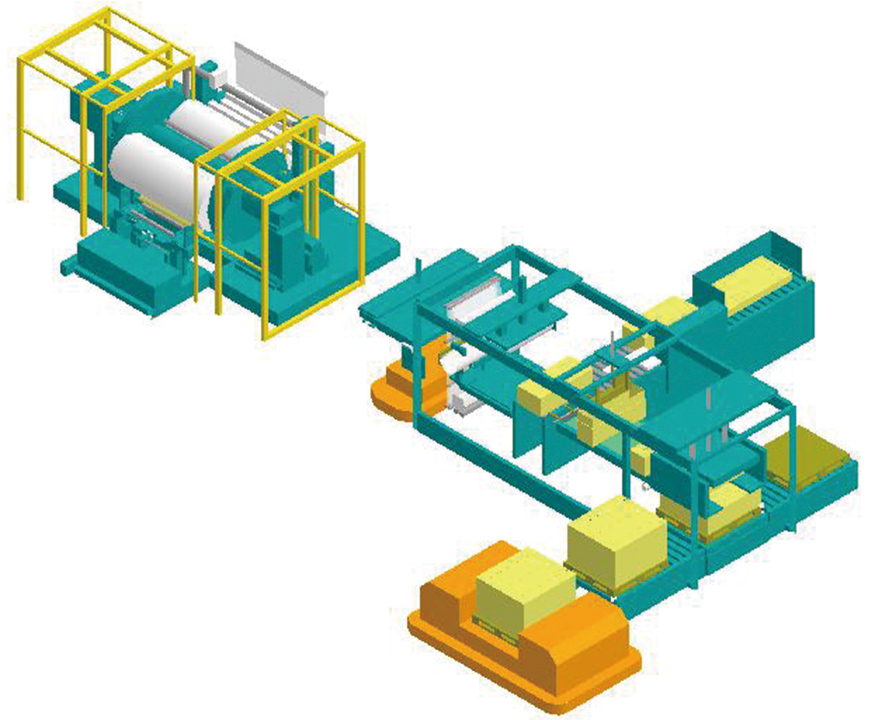

Mill Roll Winding Machine for EVA Film

Description

Enables automatic interchange between mill roll winding machine and baler

Features

- We can propose machines and systems meeting your product specifications and budget.

- Automatic turret and changing to another roll without tape

- Low-tension winding (15N or less)

- Automatic traceability management system (automatic labeling with line information and defect information)

- Excellent expandability (downstream interchange automation: labor-saving in transport between AGV, automatic packing and warehouse)