- HOME

- Products and Services

- Film-Production Equipment

- Slitting Machines

- Optical Film Slitting Machine

Optical Film Slitting Machine

We can provide a wide range of solutions, such as machines for use in clean rooms or those capable of handling wide film.

Features

- Clean room compatible structure enables easy roll cleaning

- A new type of expansion chuck minimizes particle generation problems, and achieves high-accuracy cleanliness

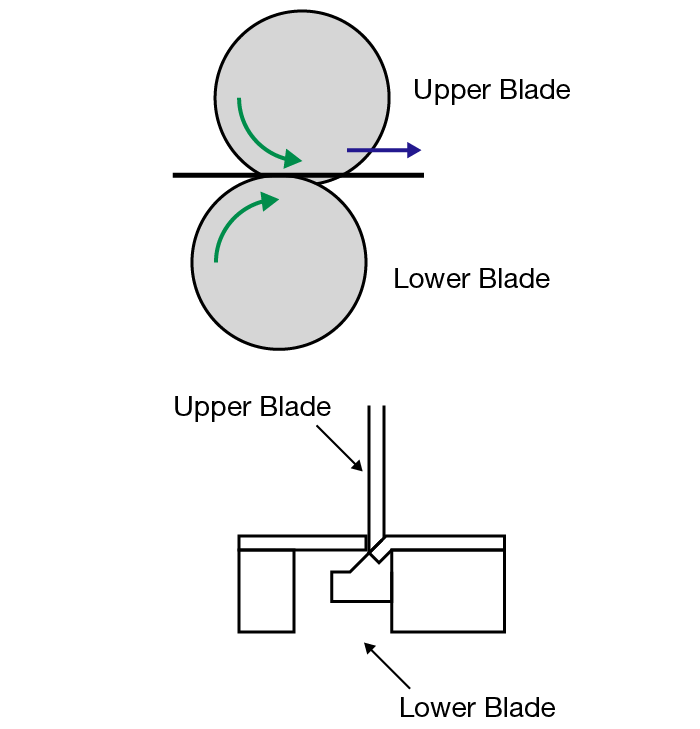

- Equipped with automatic positioning unit for shear cutter upper and lower blades. Our upper and lower shear cutting includes blade automatic positioning.Can flexibly handle multiple product types.

- Improves quality of wound product using a horizontal movement method for winding arms

Proven track record

optical film, adhesive materials, tape materials, medical supplies, capacitors, LIBs, separators, dry film photoresist, copper clad laminate, etc.

Specification

| Substrate width | Max.1,900mm |

|---|---|

| Machine speed | Max.300m/min |

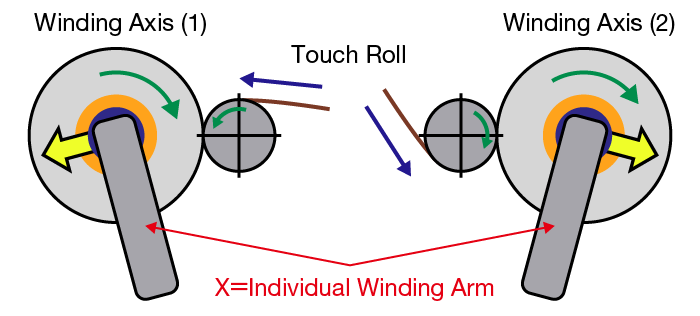

| Winding Method | 3 upper/lower 2-level horizontally moving winding arms (supports 3 rows) |

| Cutting method | Gang cutting method, Shear cutting method, Individual shear cutting method |

Cutting Method

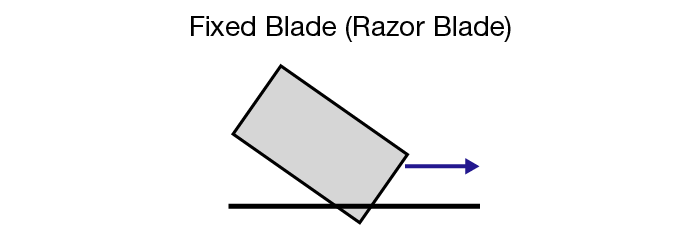

Razor Cutting

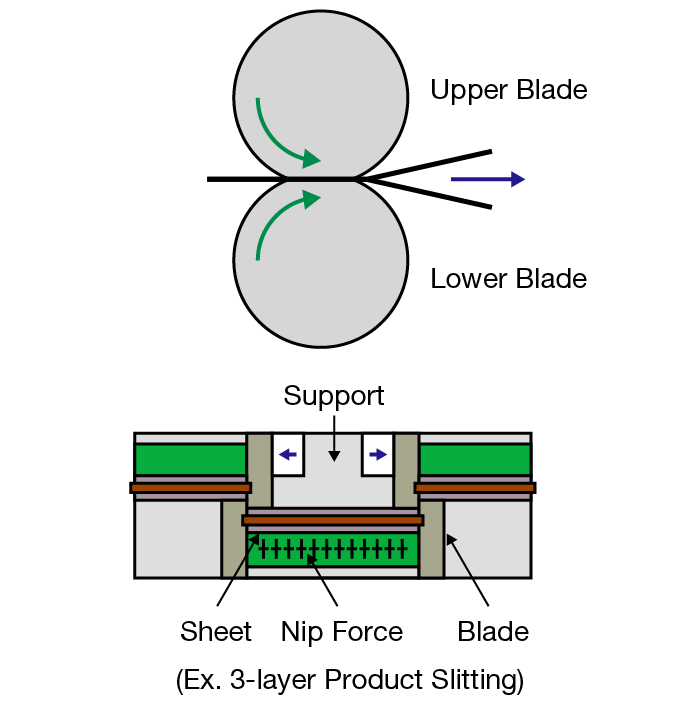

Shear Cutting

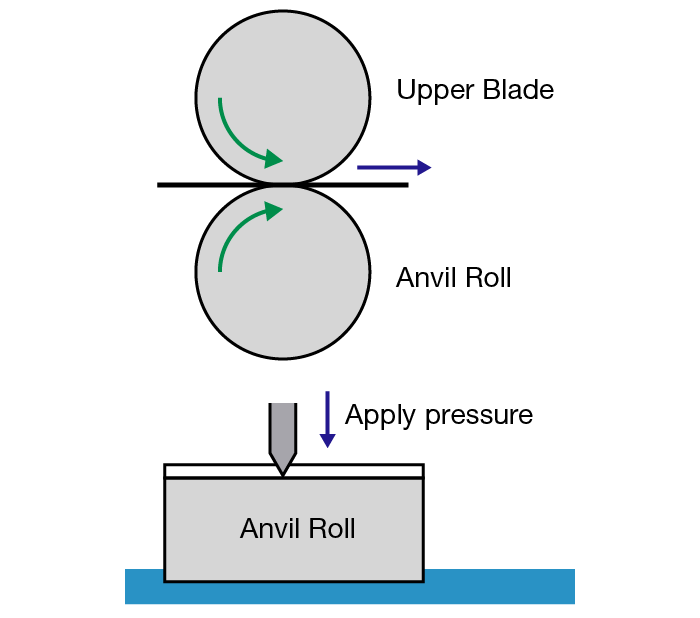

Score Cutting

Special Gang Cutting

Special Gang Cutting

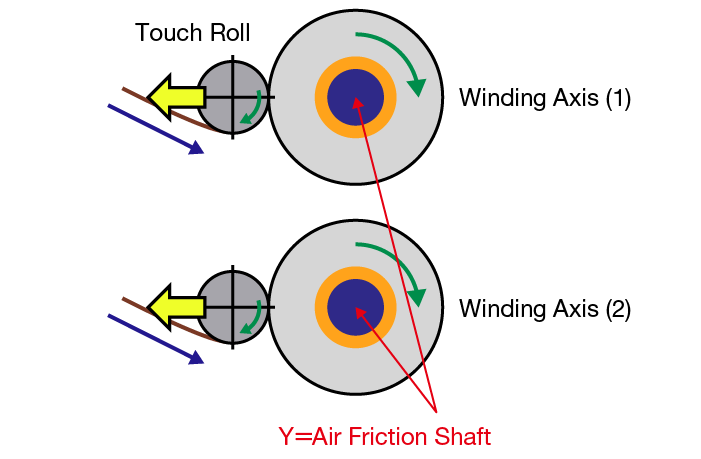

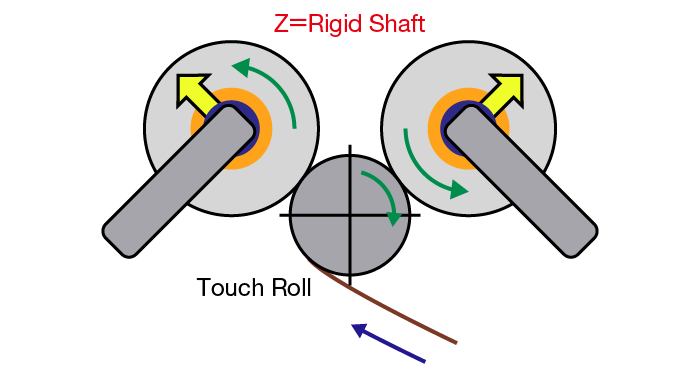

ZA Type (2-axis winding, front and back)

ZB Type

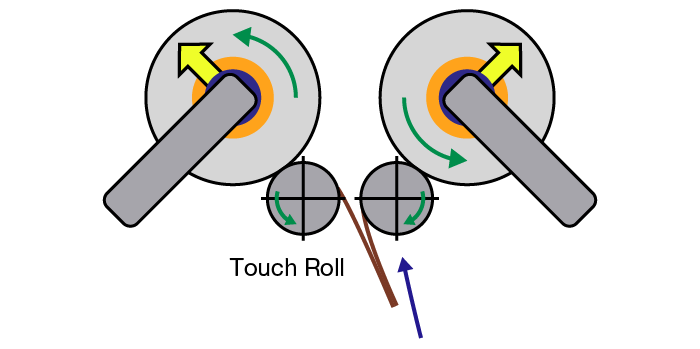

YD Type (2-axis winding, up and down)

YC Type(2-axis winding, up and down)

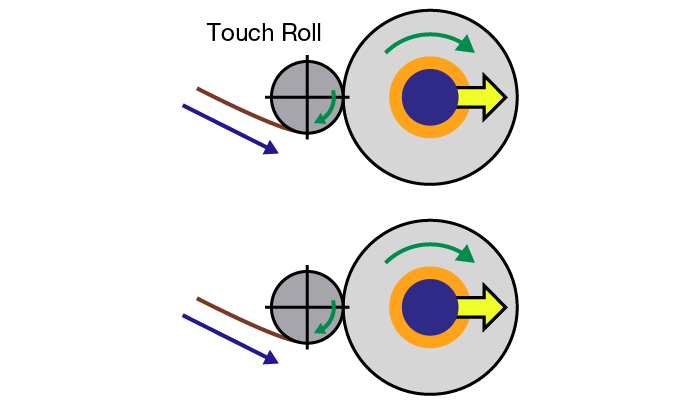

XC Type(Individual winding, front and back)