- HOME

- Products and Services

- Semiconductor-Production Equipment

- Coating Equipment for advanced semiconductor package

- TRENG-PLP Coater

TRENG-PLP Coater

Panel-Level Coating Equipment for Advanced Semiconductor Packaging

Overview

Equipment for advanced semiconductor packaging, utilizing our high-accuracy coating and large glass handling technologies established in the display industry.

Features

High-accuracy coating technology

- Timely development and high-quality coating enabled by in-house production of key devices.

- Proven top-tier performance in LCD applications requiring high color uniformity and precise film thickness control.

- Compatible with a wide range of materials from low to high viscosity.

Total process proposal from coating to drying

- Integrated line proposal covering cleaning, coating, drying, and curing.

- Process support using our demo line.

Warped substrate handling

- Proprietary warp correction mechanisms in each process unit for uniform film coating.

- Compatible with common warp shapes (Smile/Cry).

Applications

- Glass core substrates

- Glass carrier substrates

- 2.1D

- 2.3D

- 2.xD

- FOPLP (Fan-Out Panel Level Packaging)

- Organic interposers

- RDL (Redistribution Layer)

- PID (Passivation/Insulation Layer)

- Plating resist

- Carrier release layer

Specifications

| Substrate Size | Up to 600 × 600 mm |

|---|---|

| Coating Materials | PID, PR, TBDB |

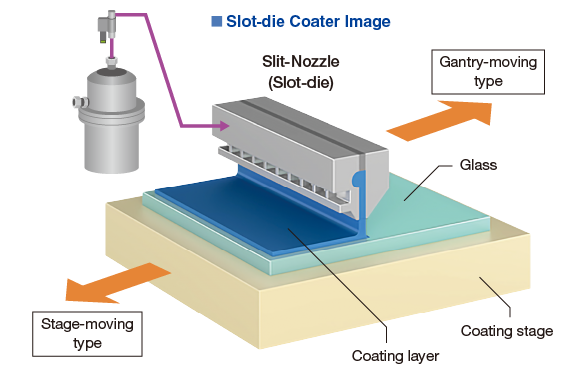

| Coating Method | Slit-die dispensing, Substrate stage moving |

| Viscosity Range | 1 cP to 1,000 cP * |

| Options | Vacuum chamber dryer system, Hot plate/Cold plate, EFEM, Inline inspection units (visual, film thickness, substrate warpage, substrate stress inspections) |

- Coating of materials with viscosity above 1,000 cP availabe as an optional. Please contact us for details.

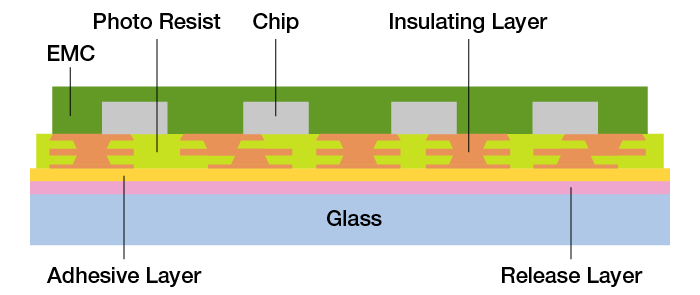

Example of Semiconductor Packaging Application

| Layer | Release | Adhesive | Insulating | Insulating | Resist |

|---|---|---|---|---|---|

| Viscosity | 6 cP | 110 cP | 20 cP | 360 cP | 13.5 cP |

| Thickness | 0.5 um | 10 um | 10 um | 50 um | 12 um |

| Uniformity | 2.7% | 2.3% | 1.8% | 2.5% | 2.3% |

| (E.E.10mm) |