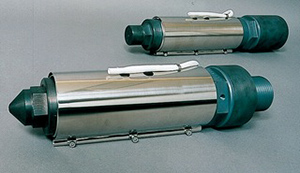

Mixing Nozzle for Injection Molding Machines

TMN16/20/30/40 series

TMN16/20/30/40 series of mixing nozzles for injection molding machines

This distinctive device eliminates uneven coloration in injection molding machines. It was developed as an application of Toray Engineering's highly-regarded static in-tube mixer and makes full use of Toray's sophisticated polymer technology.

There is no need to modify injection-molding machines already in operation. Merely replace the current nozzle with this mixing nozzle, and you can improve profitability through higher and more stable quality of molded products, and reduced usage of colorants.

Features

- Eliminates uneven coloration of molded products.

- Reduces coloring and resin changeover time.

- Shortens molding shot cycle length.

- Reduces costs by raising the master batch multiplication factor.

- Improves dimensional accuracy and quality of molded products.

- Improves mechanical strength of products molded from engineering plastic resins.

Eliminates uneven coloration of molded products.

Internally, this device employs Toray’s static in-tube Hi-Mixer to improve the color dispersion of the master batch and eliminate uneven coloration.

Reduces coloring and resin changeover time.

The inside of the nozzle is constructed with no parts where fluid can stagnate, and the flow speed is high right up to the tube inner walls. This makes it possible to shorten coloring and resin change-over time.

Shortens molding shot cycle length.

Molding shot cycle length can be shortened by reducing back pressure.

Reduces costs by raising the master batch multiplication factor.

Better dispersion of molten polymer tends to make colors deeper. This helps to reduce cost by raising the master batch multiplication factor.

Improves dimensional accuracy and quality of molded products.

By ensuring the uniform dispersion and temperature of molten polymer, this unit can reduce molded product strain and sink marks, improve dimensional accuracy, and produce more stable quality.

It also reduces the occurrence of molten polymer burning, and thus decreases the raw materials loss/product defect rate.

This unit is ideal for crystalline polymers and other colorless molded products.

Improves mechanical strength of products molded from engineering plastic resins.

The unit thoroughly kneads molten polymer, improving the mechanical strength and other properties of molded products in tension and bending strength tests.

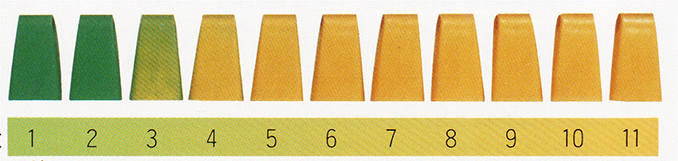

An example of color switching using this mixing nozzle

Particle diffusion test performed by microscope

Particle Diffusion Test (Photo of MICROSCOPE)

| When not using Toray mixing nozzle | When using Toray mixing nozzle |

|---|---|

|

|

Materials

| Element | Stainless steel (SCS-14 Eq. To ANSI 316) |

| Body case | Chrome Molybdenum Sheet (SCM-435 Eq. To ANSI 4135) |

| Nozzle tip | Chrome Molybdenum (SCM-435 Eq. To ANSI 4135) |

| Band heater | Stainless steel (SUS304,220V,1P) |

Specifications

| Model | Mold clamping force of injection molding (tons) | Injection amount (g) |

|---|---|---|

| TMN16 | ~150 | ~280 |

| TMN20 | 70~400 | ~2,200 |

| TMN30 | 300~1,500 | ~8,000 |

| TMN40 | 1,000~ | ~20,000 |

Other

Tip R machining, threading for attachment to injection molding machine, threading for thermocouple mounting, special-order dimensions, and other individual specification matching are also available (requires prior consultation)

Inquiries

- CONTACT US

-

+81-3-5962-9777