Oxygen AnalyzersMeasurement Principles/Model Selection/Maintenance Sites

Measurement Principles/Model Selection/Maintenance Sites

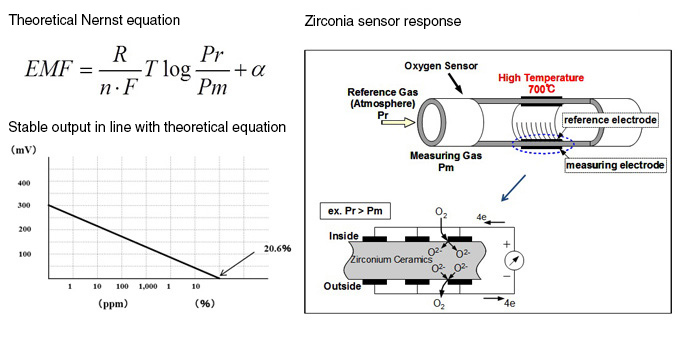

Measurement principles of zirconia oxygen analyzers

When zirconia ceramics which have undergone electrode machining on both sides are placed at high temperature, oxygen molecules on the electrode section of one side ionize, while oxygen molecules on the other electrode section are converted back into oxygen molecules. This property is called the ion conduction. The amount of the ion conduction increases as the difference in the oxygen concentration on the two sides of the zirconia ceramic increases. Electrons are passed between the two electrodes, and the amount of the ion conductance (that is, the difference in the oxygen concentration on the two sides of the zirconia ceramics) can be measured as the electromotive force between the two electrodes. As the following figure shows, this electromotive force produces a stable figure in accordance with the Nernst equation, so Toray’s zirconia sensors can measure oxygen concentration values reliably and stably.

General notes on use of zirconia oxygen analyzers

- Oxygen analyzers cannot be used in explosion-proof zones because they contain electrical furnaces.

- If flammable gas (e.g. hydrogen, methane, alcohol, or carbon monoxide) enters the oxygen analyzer, it will cause a combustion reaction and result in measurement error.

- Organic silica (used for sealants, etc.) will cause sensor degradation. (This is one of the extremely common cause of sensor degradation.)

- Halogens (especially chlorine) cause sensor failures.

- If substances with high calorific value such as carbon monoxide intermittently enter the oxygen analyzer, the sensor will accumulate a heat history, and this will cause sensor malfunction.

- If large amounts of corrosive gasses such as NOX or SOX enter the oxygen analyzer, they will cause sensor malfunction.

- At high temperatures, Freon gas may cause a separation reaction, resulting in sensor degradation.

- Water droplets, dust and mist will damage the sensor, shorten its service life, and cause errors. When measuring gasses containing them, remove them before supplying the gas into the oxygen analyzer. Please consult with us regarding removal methods before purchasing an oxygen analyzer.

Model selection chart

Please use the chart below to help you choose the appropriate model.

| Applications | Model | Description | Other options |

|---|---|---|---|

| Semiconductors, LCD, and electronic components |

MS-500 | For mounting on systems such as semiconductor manufacturing equipment; up to 8 measurement points | |

| LC-450A | Capable of measurement in ppm; AC powered |

|

|

| LC-450D | Capable of measurement in ppm; DC powered | ||

| LC-860 | Capable of measurement in ppb; AC powered | ||

| SD/LD-450 | With vacuum chamber (for installation in systems) | AC power unit: DU-450 | |

| Baking furnaces, N2 reflow ovens, and dirty gas |

RF-400 | Baking furnaces with oxygen sensor protection; exclusively for reflow oven |

|

| LC-750H/PC-111 | For high and medium concentration dirty gas, built-in gas suction pump | ||

| Gas plant, air separation | LC-750H | General type for high and medium concentrations | |

| LC-750H/PC-110 | For clean gas of high and medium concentrations; built-in gas suction pump | ||

| LC-750L | General type for low concentrations | ||

| LC-750L/PC-120 | For low-concentration clean gas, built-in gas suction pump | ||

| Vacuum deposition, sealed furnaces, and gloveboxes |

SD/LD-450 | Separate sensor and converter; thin, wall-mount converter | AC power unit:DU-450 |

| Food packaging | LC-450F | For sampling after gas filling (sampling probe) |

|

| LC-750F | For sampling after gas filling (syringe) | ||

| LF-200 | For installation in gas filling automatic packing machine |

|

Oxygen analyzer maintenance sites

The following sites in Japan and abroad provide maintenance services for Toray oxygen analyzers.

- Japan

Toray Engineering D Solutions Co., Ltd. TEL:+81 -77-544-1621

1-45, Oe 1-chome, Otsu, Shiga 520-2141, JAPAN - Korea

PnK system Inc. TEL:+82-31-376-8531

#708, 878, Dongtansunhwan-daero, Hwaseong-si, Gyeonggi-do, 18469, Republic of Korea - China

Toray Engineering (Shanghai) Co., Ltd. TEL:+ 86-21-5241-7700

Room01 36th Floor,Zhao Feng Plaza, 1027 Chang Ning Road Chang Ning Area, Shanghai 200050, China - Taiwan

Thales System Co.,Ltd. TEL:+886-3-657-2270

1F.,No.81,S.Sec.,Xianzheng 2nd Rd., Zhubei City,Hsinchu County 302,Taiwan (R.O.C.)

Environmental Technology Company TEL:+886-7-312-2698

16F.,No.255-2,Jiouru 2nd Rd.,Sanmin Dist.,Kaohsiung City 807,Taiwan

EQP Series Co.,Ltd. TEL:+886-2-2601-3667

No.3 Lane 6 Ren-ai Rd Sec.2 Linkou Township,Taipei County 224, Taiwan - Philippines

RCLL Trading Corp. TEL+63-2-533-5565

No.28 San Roque Street, Mandaluyong City, Philippines - Thailand

Citigas Co., Ltd. TEL:+66-2-920-8990

189/194 Moo. 5 Soi Liabklongbangpai, Junthongeiam Rd., T. Bangrakpattana

A. Bangbuathong, Nonthaburi 11110, Thailand - India

S.V. SCIENTIFIC TEL+91-80-2356-7255

No. 23/A, 2nd Floor, Serpentine Road, Kumara Park West,Bangalore 560-020, India - Indonesia

PT.REXINDO OTOTEKNIK TEL+62-21-8273-5509

Jl. Jambu 4, No.65 A RT. 02/08, Kel. Jatimulya Kec. Tambun Selatan Bekasi 17510 - U.S.A.

RKI Instruments Inc. TEL:+1-510-441-5656

33248 Central Avenue Union City, CA USA - U.K.

Weatherall Equipment & Instruments Ltd TEL +44 (0)1296 622 180 Unit 1 Station Approach Wendover Bucks. HP22 6BN England

Maintenance site information

Inquiries

- CONTACT US

-

East Japan : +81-3-5962-9775

West Japan : +81-77-544-6224