Water Quality AnalyzersTotal Oxygen Demand (TOD) Automatic Analyzers

TOD-200 series

TOD-200 series of water quality analyzers

TOD-200 series of water quality analyzers

The Toray TOD automatic analyzers rapidly and accurately perform automatic analysis of total oxygen demand such as in rivers, lakes and marshes, sea areas and plant wastewater, by online or offline.

These TOD analyzers measure concentration differences using the zirconia solid electrolyte sensor developed by Toray, capable of producing high-precision, high-stability results for long periods. This analyzers, are based on our technology over 45 years and plentiful track records, are economical priced, easy operating, high-reliability, and high-maintainability.

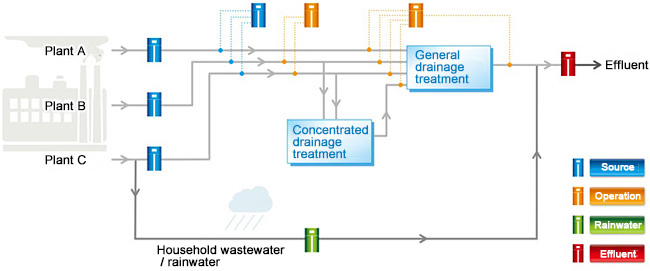

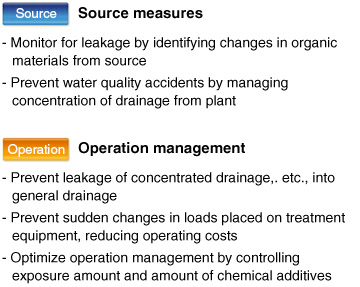

Application

Our TOD analyzers support various measurements points, from high concentration to low concentration, such as from wastewater to rainwater, and providing stable measurement.

Features

- Easy to maintain and manage, without the need for expensive test reagents

- Detectors use highly reliable special zirconia sensors

- Unique catalyst design and pre-processing filter ensure stable measurement of samples containing high concentrations, such as suspended matter and seawater samples

- 8 streams can be measured by each unit. Offline measurement is also possible

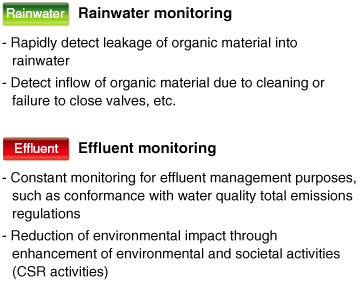

- Lineup of four models to suit individual uses

Specifications

| Shared specifications | TOD-200 series | |

|---|---|---|

| Measurement range | Low concentration specifications | 0-50~500 mg/L |

| High concentration specifications | 0-500~5000 mg/L | |

| Measurement mode | Online/offline (multistream specifications: capable of random measurement) | |

| Measurement cycle | 5 minutes or greater (freshwater specifications), 6 minutes or greater (seawater measurement) | |

| Measurement method | Automatic intermittent sealed combustion oxygen concentration difference detection method | |

| Measurement value conversion function | Contains function for converting from TOD to COD or BOD (conversion value = a+bx, coefficients a and b are customer-defined) |

|

| Linearity/repeatability | The greater of the following: ±2.5% FS or less or ±2.5 mg/L or less | |

| Zero/span stability | The greater of the following: ±2.5% FS/day or less or ±2.5 mg/L/day or less | |

| Ambient temperature change | The greater of the following: ±2.5% FS/5 deg or less or ±2.5 mg/L/5 deg or less | |

| Measurement value output | DC 4 to 20 mA (load resistance: 0 to 500 Ω) | |

| Transmission output | USB (options: RS-232C, RS-485) | |

| Input signal | Non-voltage contact, DC24V Items: External link, stop measurement, release alarm multistream: Per-stream measurement start signal |

|

| Output signal | Non-voltage contact, AC 125 V 1 A (resistance load) Maintenance in progress signal, power failure signal, external pump signal, count signal, selectable output |

|

| Abnormal measurement value (selectable output) | Upper upper limit, upper limit, lower limit, lower lower limit multistream: Per-stream abnormal measurement value signal output | |

| Device error (selectable output) | Abnormal temperature, sample supply interrupted, pipe cleaning fluid supply interrupted (can be assigned as desired for major/minor failures) (Options: Gas pressure drop, test reagent supply interrupted, cleaning fluid supply interrupted) |

|

| Other options | Recording meter, automatic calibration function, separate printer, electrical component air purge | |

| Sample conditions | ACF inlet: 0.05 to 0.15 MPa, 3 L/min or greater, 1 to 50°C (consult with us regarding situations in which the temperature will normally be 40°C or greater) (Device inlet: 0.02 to 0.1 MPa, 500 mL/min or greater, 1 to 50°C) |

|

| Offline sample amount | 100 to 200 mL/3 measurements | |

| Test reagent (optional) | None

|

|

| Cleaning fluid | Distilled water | |

| Reverse cleaning water | 0.1 to 0.4 MPa flow: 3 to 5 L/min, 1 to 50°C (do not use reverse cleaning water which contains organic carbon or detritus, etc., or which chemically reacts with samples) |

|

| Pipe cleaning water | 0.02 to 0.05 MPa, 0.4 to 0.6L/min, 1 to 50°C (do not use water which contains organic carbon or detritus, etc.) |

|

| Carrier gas | 0.3 MPa high-purity nitrogen, approx. 7 Nm3 /month (99.99% or above, no organic elements, water, or detritus, etc.) |

|

| Power | AC 100 V ± 10 V 850 VA, power consumption: Approx. 550 W (multistream model: 650 W) | |

| Installation location | Indoors 1 to 40°C (avoid environments with corrosive gasses such as hydrogen sulfide) | |

| External dimensions/weight | 550 mm (W) ×538 mm (D)×1430 mm (H)mm(not including 70 mm casters), Approx. 100 kg | |

| Anchor mounting dimensions | 4-φ13 510 mm (W) ×457 mm (D) | |

| Service area | Front, left, and right sides 600 mm (not needed for rear side) | |

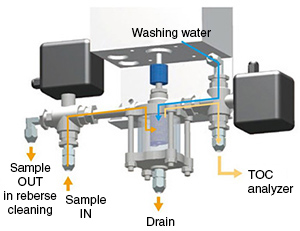

Automatic cleaning filter

Our automatic cleaning filters, developed in-house, are sample filtration preprocessing devices which consist of net-less elements made up of stacked circular disks and cleaning blades. The ACF element component uses a roughly 100 gauge net (equivalent to 147 μm) to catch matter suspended in samples.

The suspended matter is scraped off by the cleaning blades, washed off by the flow of excess sample, and evacuated via the drain.

Options such as a reverse cleaning function using cleaning water and functions for controlling element pass-through time are also available to reduce the amount of element clogging.

Inquiries

- CONTACT US

-

East Japan : +81-3-5962-9775

West Japan : +81-77-544-6224